This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

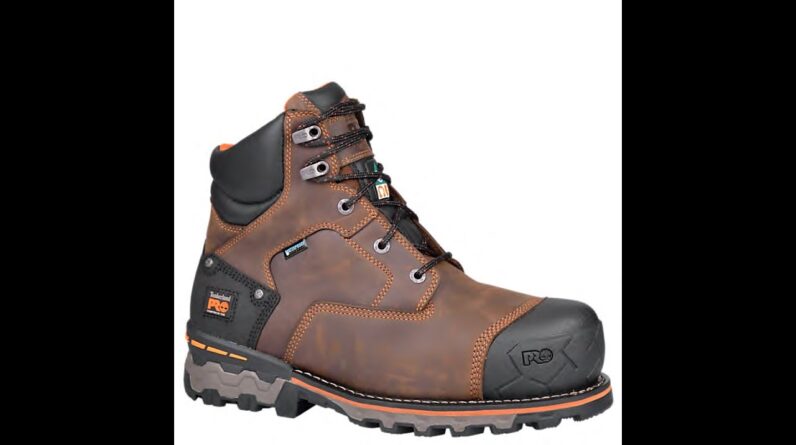

The Timberland Pro Series Work Boots

Welcome back, and today we’ll be focusing on a pair of Timberland Pro Series work boots that have recently been outfitted with new soles. These work boots come with a unique combination of a steel toe and a metatarsal guard integrated into the tongue, making them an excellent option for those working in extreme conditions that demand foot protection. These work boots provide superior durability and support and are a testament to American quality and craftsmanship.

Metatarsal Guard – An Added Layer of Protection

What sets these work boots apart from other models is the inclusion of a metatarsal guard integrated into the tongue. This feature is not always visible to the naked eye, as many work boots often have external metatarsal guards that are laced on, which can make them bulky and cumbersome. Having a metatarsal guard is incredibly crucial, as it deflects any heavy objects that may land on your instep, preventing painful injuries.

A Popular Choice for Foundry Workers

These work boots are particularly popular among foundry workers, who put these boots through hell and back. The local foundry where these boots are worn primarily deals with pouring iron and steel, exposing the boots to scorching temperatures of 2100°F to 4000°F (1149°C to 2204°C). These extreme conditions make durability an absolute necessity for these boots.

Examples of The Abuse These Boots Endure

To illustrate just how harsh these conditions can be, take a look at these images of work boots before and after they were sent to the foundry. Notice the steel and iron pellets embedded into the soles of the boots, a product of the high temperatures they’ve been exposed to. Additionally, the boots are covered in a silica dust, a byproduct of the sand used to break the molds at the foundry. This environment places significant demands on work boots, and withstanding these elements is no easy task.

Reshaping the Future with New Soles

To give these boots a new lease on life, the worn-out soles were replaced with the Vibram® number 100 Soles. These soles have a reputation for versatility, having conquered Mount Everest with climbers at temperatures of -60°F (-51°C) and proving their durability in the hot confines of the foundry. Coupled with its heat-resistant qualities, the Vibram number 100 is the perfect choice for those looking to extend the lifespan of their work boots, with some even opting to get two pairs of boots for alternating wear.

An Honor to Repair and Restore These Boots

It is a real honor to work on these boots and help support the hardworking individuals who continue to contribute to America’s growth and prosperity. Despite steel and iron foundries in the United States being virtually non-existent anymore, these workers continue to uphold the quality and expertise that the industry demands. Working on these boots for over 25 years, we have maintained relationships with these workers and companies and taken pride in delivering exceptional results.

A Message of Appreciation

We’d like to extend our thanks to everyone who took the time to watch our video and learn more about the restoration and repair of these Timberland Pro Series work boots. As we go about our day-to-day lives, it’s essential to remember those who make it possible through their hard work and dedication to their trade. So, support American workers today and have a wonderful day!

Hello once again I am very imp with your work. I didn't get a response the first time I commented on this video. I ended up getting rid of my Timberlands. But I replaced them with a pair of Georgia boots that will need to be re soled soon. I would like to know where are you located, and the price for your services too.

Thank You in advance.

Excellent work👍🏼 congratulations. How much does it cost to resole a pair of work boots?

I have a pair of timberland pro direct attach, and I would like to know if they can be fixed.

Thanks in advance.

I can only imagine the amount of hard work someone has to put into a project like this. The result is astonishing but I wonder, is it possible to "resole" normal 6 inch timberland boots?, I heard someone saying that it was difficult due to timberland having an specific method but reading the answer from an actual professional means way more to me.

Hi i was under the impression that its difficult to resole Timberland Pro boots, i have Timberland Pro Pitboss boots, that have no tread left, do you know if they can be resoled. best regards keep up the good work.