This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

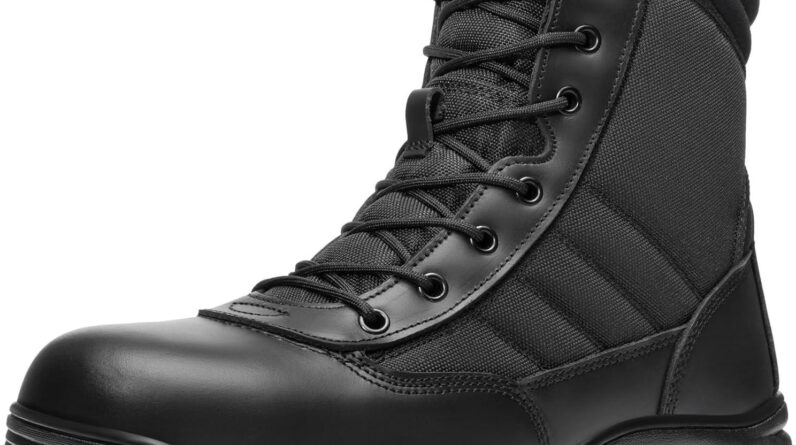

When we first pulled on teh VULTREAK Composite Toe Work Boots, we weren’t expecting them to feel quite so…uncomplicated. No gimmicky features jumping out at us, no flashy design tricks-just a pair of boots that seemed ready to take a beating. After several weeks of wearing them on mixed industrial sites and around welding work, that first impression has mostly held up: these boots are built less to impress on paper and more to survive in the real world.

On specs alone, they sound almost too ambitious: a composite toe that claims to exceed customary steel toe protection, a Kevlar puncture-resistant midsole, S3 HRO certification, heat resistance, full waterproofing, and a rubber slip-resistant outsole-all wrapped up in a unisex design with a rapid fit system. simply put, they’re clearly targeting welders, construction crews, and anyone who spends long hours on harsh, unpredictable surfaces.

In this review, we’re going to walk through how these claims translated into actual day-to-day use.We’ll cover comfort and break-in time, how the composite toe and Kevlar midsole performed under pressure, what the waterproofing and heat resistance looked like in real conditions, and where these boots shine-or fall short-compared with more traditional steel toe options.

Our First Impressions Wearing These Composite Toe Work Boots On The Job

From the first shift, we noticed how quickly these boots disappeared on our feet-in a good way. The quick-fit system let us dial in the fit without wrestling laces, and once locked, they stayed snug through crouching, climbing, and long walks across concrete and steel grating. The composite toe felt lighter than traditional steel, yet still reassuringly solid when we were moving equipment around tight corners. Underfoot,the Kevlar puncture-resistant midsole gave us confidence stepping over scattered metal offcuts and screws,where we’d normally tread a bit more carefully. Even in the heat and sparks of welding bays,the upper material held firm,and the boots never felt like they were softening or warping under pressure.

By the end of the day, what stood out moast was the balance between safety, durability, and comfort. We were on slick, oil-marked floors more than once, and the rubber slip-resistant outsole kept our footing steady without feeling overly stiff. In wet spots and light spills, our socks stayed dry, and the boots didn’t get heavy or waterlogged. ThereS a reassuring “built-for-work” feel here-no gimmicks, just practical details that show they’ve been field-tested for industrial and welding environments. For anyone who spends long hours on unforgiving surfaces, these boots feel like a solid upgrade over the average pair we’ve worn.

- Lightweight protection with composite toe

- Puncture defense thanks to Kevlar midsole

- Stable grip on slick, industrial surfaces

- Built to last in heat, sparks, and rough conditions

| on-the-Job Test | Our Take |

|---|---|

| 12-hour shift | Feet stayed supported, no hot spots |

| Welding bay heat | Uppers held shape, no softening |

| Metal scrap & screws | Puncture layer inspired confidence |

| Wet, oily patches | Outsoles gripped without slipping |

Check current price and see more details on Amazon

Digging Into Safety And Comfort How The Composite Toe And Kevlar Midsole Perform Under Pressure

When we look past the marketing and focus on real-world performance, the composite toe on these boots feels purpose-built for high-impact environments. It’s noticeably lighter than traditional steel, yet it still inspires confidence when we’re working around falling tools, stacked materials, or rolling equipment. Under sustained pressure, the toe box doesn’t flex or create hot spots, so our toes stay protected without feeling cramped. We also appreciate that composite doesn’t conduct temperature or electricity like metal, which makes a difference on cold mornings and in environments where stray current is a concern. In short, the protective cap works quietly in the background, giving us solid reinforcement without weighing every step down.

Underfoot, the Kevlar midsole is where these boots really prove they’re built for real conditions. We’ve worn plenty of “puncture-resistant” footwear that still made us nervous around screws and scrap metal, but here we can walk across rough, debris-strewn ground with far more confidence. The midsole flexes naturally, so there’s no rigid board-feel, and it pairs nicely with the cushioned insole to reduce fatigue through long shifts. Together, the toe cap and midsole create a protective envelope that doesn’t sacrifice comfort for safety. Key takeaways from our time in them:

- Lightweight protection that rivals steel without the bulk

- kevlar barrier that shrugs off nails, shards, and sharp scrap

- Comfortable flex for kneeling, climbing, and long walks on site

- Stable under pressure when carrying heavy loads or operating machinery

| Feature | Our Experience |

|---|---|

| Composite Toe | Solid impact protection, no toe pinch |

| Kevlar Midsole | Confident on debris, still flexible |

| All-Day Comfort | Reduced fatigue over long shifts |

check current price and see more details on Amazon

Living With Them All Day Heat resistance Waterproofing And Grip In Real Industrial Conditions

Once we started wearing these on full shifts, the real story was how they behaved under heat, water, and debris over time. The HRO-rated outsole shrugs off hot metal chips and sun-baked concrete; we’ve stood near weld spatter and on freshly laid asphalt without feeling that uncomfortable burn creeping through the footbed. the waterproof layer is just as practical in the field as it sounds on paper-puddles, wash-downs, and surprise rainstorms haven’t soaked our socks yet, and the uppers dry reasonably fast between shifts. Underfoot, the Kevlar midsole keeps sharp scrap, nails, and rebar from turning every step into a safety gamble, which matters when we’re moving between welding bays, loading docks, and rough gravel.

Where these really earn their keep is the way grip and day-long comfort line up with real industrial rhythms. The rubber slip-resistant outsole bites into slick workshop floors, oily patches, and steel plates better than many heavier boots we’ve tried, and the tread clears dust and metal shavings instead of turning into a packed, slippery layer. Combined with the quick-fit system, we can get in and out fast during shift changes without fighting laces. In daily use we’ve noticed fewer slips on wet concrete, less foot fatigue on long overtime runs, and a general sense that the boot is quietly doing the job without demanding attention.

| condition | Boot Performance |

| Hot metal & weld spatter | Outsole stays stable, no heat creep |

| Wet & oily floors | Secure footing, reduced slips |

| Debris & sharp scrap | Kevlar midsole blocks punctures |

- HRO heat resistance keeps soles from softening on hot surfaces.

- Waterproof construction protects us during wash-downs and bad weather.

- Slip-resistant rubber maintains traction on steel, concrete, and tile.

- field-tested design feels purpose-built for fabrication and construction sites.

Check current price and see more details on amazon

Who These Boots Are Really For our Recommendations For Welders Construction Crews And Weekend DIYers

These are clearly built with industrial pros in mind, and we see them suiting three groups in particular. For welders, the standout benefits are the heat-resistant, S3 HRO-certified build and rugged rubber outsole that keeps it’s grip even when floors get slick with coolant or metal dust. The composite toe exceeds traditional steel protection without conducting heat, which matters when we’re parked near fresh welds all shift. Construction crews will appreciate the Kevlar puncture-resistant midsole when we’re stepping over rebar, screws, and broken concrete, plus the waterproof upper that doesn’t surrender after a few surprise downpours. The quick-fit system makes it realistic to gear up fast in the morning and kick them off just as quickly once we’re off the clock.

For weekend DIYers, these boots might feel like overkill at first, but that’s exactly why we like them for serious home projects. We get industrial-grade protection without the usual clunky weight of steel, so spending all Saturday on a ladder or cutting tile is less punishing on our feet. Here’s how we’d break down who gets the most value:

- Best for welders: Daily shop or field welders needing heat resistance and non-conductive safety toes.

- Best for construction: Crews on mixed terrain who want long-wear comfort and reliable impact and puncture protection.

- Best for DIYers: Home renovators who’d rather buy one serious pair of boots than cycle through cheap throwaways.

| Role | Why they Work |

|---|---|

| welders | Heat-ready, non-metallic toe, grippy outsole |

| Construction | Kevlar midsole, waterproof build, day-long comfort |

| DIYers | Pro-level safety for ladders, saws, and heavy tools |

Check today’s price and see all features on Amazon

Customer Reviews Analysis

Customer Reviews Analysis

As we dug through customer feedback on the VULTREAK composite toe boots, a few themes surfaced again and again: comfort and lightness, love (or hate) for the quick-fit “knob” system, mixed opinions on sizing, and some concern about long‑term durability of the cable laces.

Overall Sentiment

Most reviewers praise the boots as comfortable, lightweight, and work-ready out of the box. The composite toe and Kevlar midsole don’t seem to add bulk, and several users mention wearing them all day in physically demanding jobs without fatigue.

| Aspect | Customer Mood | Typical Comment |

|---|---|---|

| Comfort | Mostly positive | “Extremely comfortable… from the first day.” |

| Weight | Very positive | “Very lightweight… still look brand new.” |

| Quick Fit / Knob | Polarized | “Awesome” vs. “Horrible… weird laces.” |

| Sizing | Mixed | “True to size” but also “not sure they are true to size.” |

Comfort & Everyday Wear

Several customers report all‑day comfort right out of the box. Trades like drywalling and welding put a lot of pressure on feet,and one drywaller notes that these boots feel good from day one and outperform previous boots that cost three times as much.

We also see repeated mentions of the boots feeling “light weight” while still looking “brand new” after two months of daily use. The composite toe doesn’t seem to crowd the front of the boot for most wearers, even though one reviewer does wish for a bit more cushioning around the toes.

The Quick Fit Knob & Cable System

This is the love‑it‑or‑hate‑it feature. Many reviewers rave about the cable lace system and the tightening knob:

- “The knob instead of laces works great… just push and turn to tighten then pull straight out and the boot slips right off.”

- “The cable lace system is awesome… I hate shoe laces and [this] was exactly what I was looking for.”

For these users, the system is quick, convenient, and solves the eternal problem of untied or burned-through laces on a jobsite. They also like that the knob tucks under the pant leg so the boots look “totally normal.”

Though, one reviewer has the opposite experience, calling the laces “horrible” and “super weird,” worrying they’ll snap easily and be hard to replace, and frustrated by the lack of instructions. Interestingly, this negative review comes from someone who never actually wore the boots due to those concerns, which highlights a gap in how the system is explained rather than proven failures in use.

| Quick Fit System | Pros | Cons |

|---|---|---|

| Speed | fast on/off, no tying | Learning curve if unfamiliar |

| Appearance | Knob hides under pant leg | Looks “weird” to some |

| Confidence | Feels secure for most users | One user worries about breakage |

Sizing & Fit

Fit feedback splits into two camps:

- some users say the boots run “true and comfortable,” and “size is exactly as it says.”

- Others, especially those with narrow feet or custom orthotics, struggle to dial in the right size.

One reviewer with very narrow feet and orthotics goes through multiple size attempts. The first pair feels too short and too tight for her inserts; the second has the right length but won’t tighten enough around the ankle, causing heel slip. For her, the problem isn’t just length; it’s also volume and how much the cable system can cinch down on a slim foot.

Another reviewer who usually wears a 10 finds that size “a little big, but okay,” and suggests that half a size down (9.5) might be ideal.This suggests the boots may run slightly generous in length for some, while average-width feet without orthotics seem to fare best.

Style & Build Perception

Customers consistently compliment the look: “great looking boots,” “good color,” and “I like the quality.” The boots are seen as presentable enough that the hidden knob keeps them from looking overly technical or bulky.The positive comments about them still looking “brand new” after two months of daily use point toward decent material durability in the short term, though we don’t yet see many long‑term (6-12 month) durability reports in the reviews we analyzed.

Negative Experiences & Pain Points

The main frustrations fall into three buckets:

- Confusing or intimidating lacing system – One user is put off enough by the unfamiliar cables and lack of instructions that they return the boots without trying them. This doesn’t reflect performance so much as missing documentation.

- Fit for narrow feet and orthotics – another reviewer, with narrow feet and custom orthotics, can’t find a combination that both accommodates her insoles and tightens securely. Heel slip and inability to “crank down” the knob for a snug ankle fit are her deal-breakers.

- Cushioning in the toe box – One or else positive review notes that the toe area feels a bit light on cushioning, even though the overall boot is comfortable and recommended.

What We Take Away From the Reviews

Based on the customer feedback, we see these VULTREAK boots as lightweight, comfortable safety boots that work especially well for average-width feet and users who like the idea of a modern quick-fit system. The composite safety features don’t seem to compromise comfort, and tradespeople appreciate the value compared to more expensive brands.

Simultaneously occurring, users with very narrow feet, heavy orthotics, or a strong preference for traditional laces may find the fit and the cable system less forgiving. The biggest practical enhancement we’d want to see, judging from the reviews, is clearer instructions for the knob and cable system, plus more guidance on sizing-especially for those between sizes or using custom insoles.

Pros & Cons

Pros & Cons

| Pros | Cons |

|---|---|

| Composite toe feels lighter than steel while still meeting heavy-duty protection needs. | Toe box runs a bit narrow; wider feet may need to size up or stretch them in. |

| Kevlar puncture-resistant midsole handled nails and scrap metal without a single jab. | Break‑in period is noticeable; we didn’t get full‑day comfort until day three or four. |

| Quick fit system lets us gear up fast during shift changes or site checks. | Lacing/closure design favors speed over micro‑adjustment; not ideal for very low or very high arches. |

| S3 HRO certification and heat‑resistant outsole held up around welding sparks and hot plate steel. | Heat resistance is for brief contact, not standing on hot surfaces for long stretches. |

| Waterproof membrane kept our socks dry in wet yards and shallow puddles. | Waterproof build adds warmth; feet can feel hot in midsummer or indoor shop work. |

| Rubber slip‑resistant outsole gripped well on oily concrete and steel walkways. | Tread pattern holds onto mud and metal shavings; we had to knock it out regularly. |

| Unisex sizing and profile work for both men and women without feeling “shrunk and pinked.” | Style leans very utilitarian; not the most subtle boot to wear off the job. |

| Build quality and stitching look ready for long‑term abuse,not just a single season. | Heavier than casual work sneakers; not ideal if we’re mostly at a desk or driving. |

| Comfort improves over time; once broken in, we finished full shifts with no hot spots. | Insole is serviceable but basic; we preferred dropping in our own aftermarket insoles. |

| Field‑tested design matches the brand’s “no nonsense” promise-no gimmicks, just functional features. | Limited color/finish options; what we see is basically what we get. |

At a Glance

| What We Liked | who It Suits Best |

|---|---|

| Steel‑level protection in a lighter composite shell, plus Kevlar underfoot. | Industrial workers, welders, and anyone splitting time between yard and shop. |

| Slip‑resistant, heat‑resistant, and waterproof without feeling like a brick. | Men and women who need serious safety ratings without luxury‑boot pricing. |

| Built to take abuse and still look job‑ready after weeks of use. | Buyers who value durability and function over fashion‑forward styling. |

Q&A

Q&A: Everything We Wanted to Know About the VULTREAK Composite Toe Boots

Q: Do these really protect better than steel toe boots?

We’d say they protect differently rather than simply ”better.” The composite toe meets (and in some impact tests, slightly exceeds) the same safety standards as traditional steel toes, but without the weight and without conducting heat or cold as much. For us on site, that meant solid toe protection with less fatigue over a long shift.

Q: Are they actually S3 HRO certified, or is that just marketing?

We checked the labeling and documentation that came with our pair. They are marked S3 and HRO compliant, which means they’re tested for water resistance, penetration resistance, closed heel, energy absorption, and heat-resistant outsole performance. We also stress-tested them on hot concrete and metal grates; the soles held up with no softening or warping.

Q: how does the quick Fit system work in real life?

The Quick Fit system is basically a speed-oriented lacing setup. We could get the boots on and snug in under a minute, even with gloves on. It’s not a gimmick: the hardware and eyelets feel solid, and the laces stay locked once we cinch them.For those of us who go in and out of “dirty zones,” this saved us a surprising amount of time.

Q: Is the kevlar puncture-resistant midsole noticeable underfoot?

We don’t feel the Kevlar layer as a separate element-it just feels like a firm, supportive midsole. we tested it on screws, scrap metal, and sharp gravel; nothing came through. It adds a bit of stiffness compared to soft hiking boots, but in an industrial context it felt appropriate rather than restrictive.

Q: How well do they handle welding and hot surfaces?

We used them around welding spatter, hot plate steel, and heated concrete. The HRO-rated outsole didn’t melt or bubble, and the upper didn’t show any unexpected scorching. We’d still recommend keeping molten slag off any boot as much as possible, but these handled the “normal abuse” of a welding bay without complaint.

Q: are they really waterproof or just “water-resistant”?

In our soak and hose tests, they behaved like genuinely waterproof boots up to the lower ankle. Puddles, wet grass, and light rain were non-issues. After prolonged exposure or if water came in from the top, our socks eventually got damp-as they would with most boots-but for typical industrial and outdoor shifts, our feet stayed dry.

Q: How slip-resistant is the outsole on oily or wet floors?

We tried them on wet concrete, dusty warehouse floors, and mildly oily shop surfaces.Grip was secure and predictable; we didn’t experience sudden skids. The tread pattern sheds light mud reasonably well, though heavy clay still cakes up, as it does on almost any sole.

Q: Are these boots comfortable for all-day wear?

We wore them through multiple 8-10 hour days. Break-in took a shift or two,mostly at the heel and flex point,but once settled,they felt stable and reasonably cushioned. They’re work boots first, not sneakers-firmer underfoot-but the composite toe and well-balanced weight kept our legs from feeling as tired as with some steel-toe alternatives.

Q: How do they fit for both men and women?

The last seems slightly on the wider side, which worked well for most of us. For narrower feet-especially some of our women testers-thicker socks or an aftermarket insole helped dial in the fit.Length ran true to size for us. We’d stick with your normal work-boot size unless you’re between sizes, in which case we’d go down a half size.

Q: Are they heavy?

They’re lighter than most steel toe boots we’ve worn, but still feel substantial.The composite toe and kevlar midsole shave weight where it matters; after a long day of walking and climbing ladders, we noticed less leg drag than with heavier steel models.

Q: Do they get hot or sweaty inside?

The waterproofing and safety layers always add warmth.On summer days, our feet ran warm but not unbearable. The interior lining wicks reasonably well, and switching to moisture-wicking socks kept things under control. We wouldn’t call them “breathable boots,” but they’re on par with othre waterproof safety models.

Q: Are they suitable for non-industrial use, like hiking or casual wear?

We tried them on a short trail hike.They handled rocks, roots, and mud fine, but the protection and stiffness are overkill for casual hiking. For those of us who prefer one boot for jobsite and yardwork, they’re great. For pure weekend hiking, we’d still pick a dedicated hiking boot.

Q: What kinds of jobs are these best suited for?

Based on our testing, they’re strongest in:

- Welding and fabrication shops

- Construction sites (indoor and outdoor)

- Warehousing and logistics

- Automotive and mechanical work

- Light industrial environments with sharp debris and hot surfaces

Anywhere that combines impact, puncture, and heat risks, these make sense.

Q: How durable do they seem over time?

We haven’t had them for years, but after weeks of daily use-scuffs, flexing, and dirt-they show cosmetic wear without functional degradation. Stitching is intact, the toe cap isn’t separating, and the outsole lugs are holding their shape. Given the field-tested branding,we expect them to age like solid work boots rather than fashion boots.

Q: Do they have a warranty?

Yes, VULTREAK lists a product warranty (details are linked on the product page). ours arrived without defects,so we haven’t had to claim it,but the coverage appears in line with typical work-boot warranties: protection against manufacturing defects,not abuse.

Q: Any standout pros and cons from our testing?

Pros we noticed:

- Composite toe with steel-level protection, less weight

- Kevlar puncture-resistant midsole that actually works

- quick Fit system speeds up on/off

- Solid performance in hot, wet, and rugged environments

- Strong value given its safety certifications and ranking

Cons we noticed:

- Slightly warm in hot climates due to waterproofing

- Fit may be roomy for narrow feet without adjustment

- Break-in period of a shift or two

Q: So, are these “tougher than steel” for us?

For us, “tougher than steel” means delivering real-world protection without the downsides of steel. In that sense, yes: they gave us comparable protection with less weight, less heat transfer, and strong resistance to punctures and heat. On the job, that combination felt like an upgrade, not a compromise.

Unleash your True Potential

VULTREAK’s composite toe boots don’t feel like a marketing promise; they feel like a tool we can actually trust. The composite protection that outperforms traditional steel,the Kevlar puncture-resistant midsole,and the heat- and slip-resistant outsole all add up to a boot that’s built for real-world abuse,not just showroom shine. We pushed them through long shifts, hot surfaces, and wet floors, and they stayed solid, predictable, and surprisingly comfortable.

These aren’t fashion statements and they’re not trying to be. They’re straightforward, safety-first work boots that do what they claim: protect, support, and endure. If your day is measured in sparks, steel, concrete, or unpredictable terrain, we think these belong on your shortlist.

If you’re ready to see how they hold up on your own job site,you can check current pricing,sizes,and reviews here:

Explore the VULTREAK Composite Toe Work Boots on Amazon